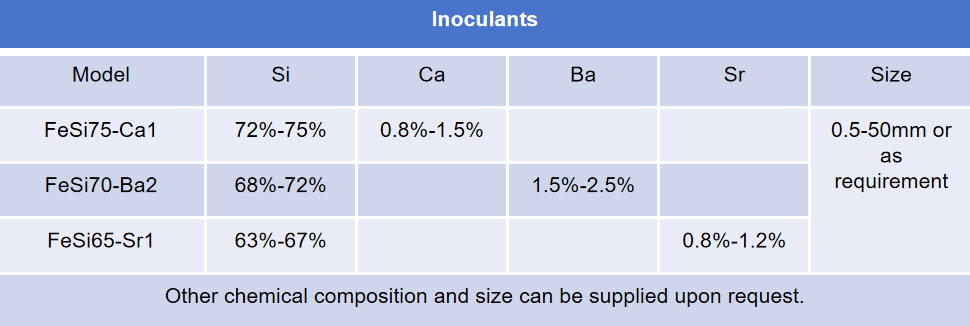

Inoculants are a crucial cast iron additive dedicated to optimizing the microstructure and mechanical properties of castings. Its core composition includes silicon (65%-75%), calcium (0.5%-2.5%) and trace amounts of barium and strontium. By providing a heterogeneous nucleation core, the inoculant effectively promotes graphitization, reduces white-mouth organization, and results in a uniform and fine A-shaped distribution of graphite, which significantly improves the strength (10%-30%) and machinability of cast iron.

The addition of inoculant has very little effect on the overall chemical composition of the liquid iron, but can deeply improve its microstructure, so that gray cast iron, ductile iron and other materials to obtain better performance. When used, the inoculant can be added to the molten iron at a ratio of 0.2%-0.6% and evenly distributed through a flow-flush or injection process, which usually completes the inoculation process within 5-10 minutes. This efficient and stable way not only helps to improve the quality of castings, but also effectively reduces the scrap rate, which is an indispensable key material in modern casting production.

Need Detailed Information or a Customized Quote?

Submit your inquiry below, and our specialists will provide a detailed response within 1 business day.

Whatsapp

Whatsapp