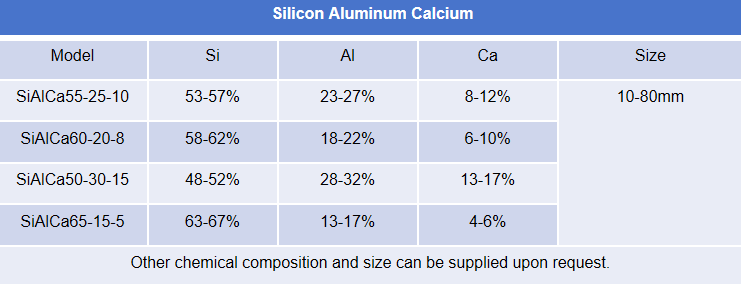

Silicon Aluminum Calcium is a composite deoxidizer composed of silicon (55%~65%), aluminum (20%~30%) and calcium (5%~10%), which is made by melting quartz, alumina, limestone and carbonaceous reducing agent in an electric furnace. Its synergistic deoxidation ability is better than that of a single element. It can efficiently remove oxygen and sulfur impurities in molten steel, while refining grains and improving steel toughness. It is widely used in steelmaking (especially stainless steel and special steel), casting and refining outside the furnace. This alloy has both cost-effectiveness and performance advantages, can reduce smelting energy consumption and improve the purity of molten steel, and is a key additive for optimizing metallurgical processes and high-end steel production.

Need Detailed Information or a Customized Quote?

Submit your inquiry below, and our specialists will provide a detailed response within 1 business day.

Whatsapp

Whatsapp